Product Information

Specification

Brand : WKSTOOL

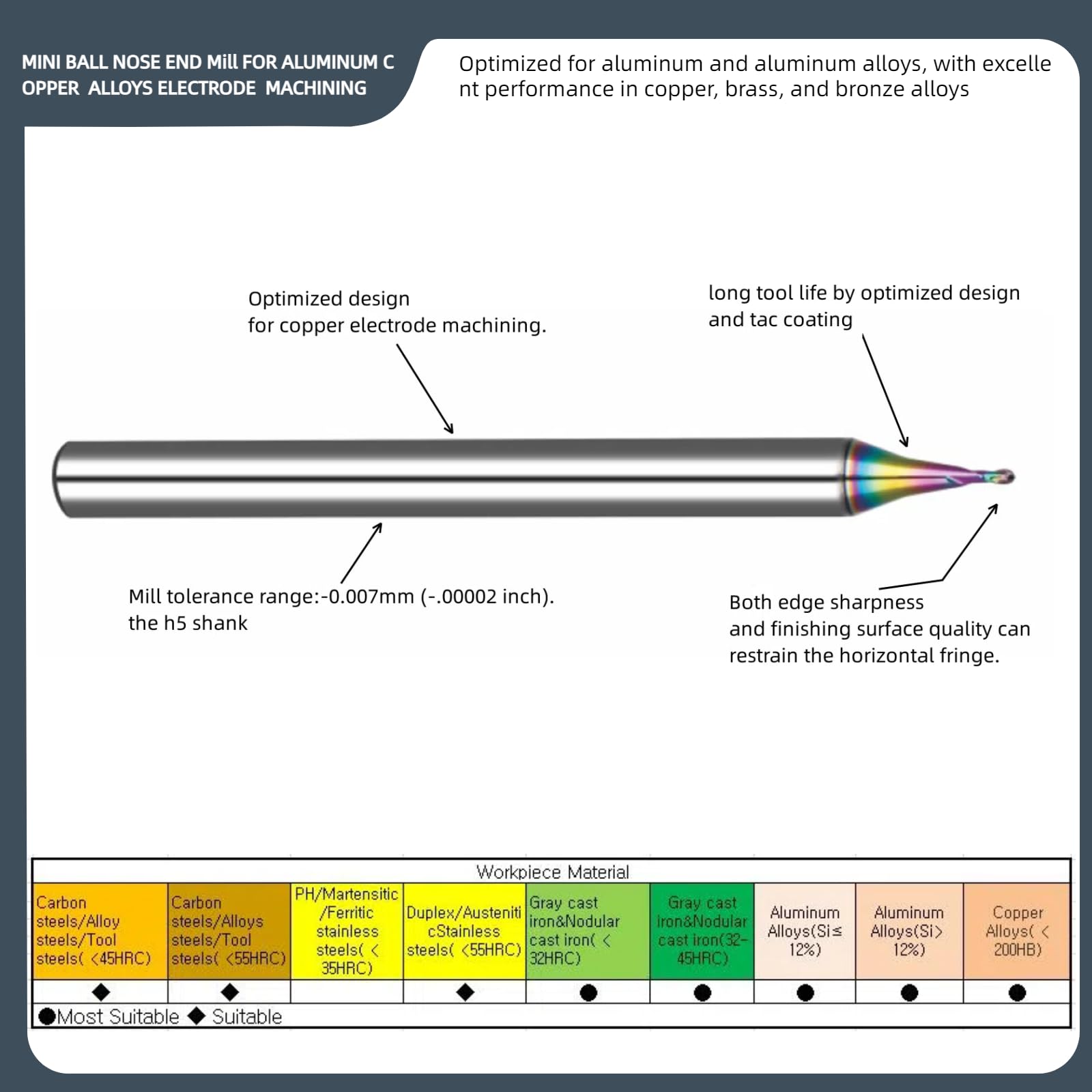

BulletPoint1 : Precision design and manufacturing:Optimized for Aluminum Alloys,Brass Bronze copper Alloys electrode machining.High welding resisitance,the high spiral angle with both edge sharpness and finishing surface quality can restrain the horizontal fringe.high quality and stable milling performance with long tool life,Round Top with 2 Flutes,35°helix,Center cutting,Premium micro grain carbide,work extremely well in materials up to 65HRC,These end mills are crafted with pinpoint accuracy,Cutting diameter tolerance:-007mm (-.00027 inch).the h5 shank tolerance ensures a snug fit in your machine.No more scrap projects or frustrating adjustments.your workpieces will meet the tightest specs

BulletPoint2 : Designed for Aluminum Alloys& copper electrode machining:the high spiral angle with both edge sharpness and finishing surface quality can restrain the horizontal fringe. All are center cutting,35° high helix angle, gives improved surface finishes at higher feed rates, especially when Slotting,Plunging,3D Contouring,Finishing,Roughing,copy milling.Delivers efficient, chatter-free machining

BulletPoint3 : Suit for CNC Router Plunge Router,and Engraving Machine.Most suitable for copper, aluminum and other non-ferrous applications.also used for machining hardened steel,Free Machining Steels,Medium Alloy Steels,Carbon Steel,Alloy Steel,Cast Iron,Mould Steel,inconel,and more.

BulletPoint4 : Durability and Heat Dissipation:Made from high-hardness tungsten steel material capable of withstanding high-intensity cutting.Tac coating enhances resilience and provides superior heat dissipation even at high speeds.Ensures durability and optimal performance throughout fast milling processes.capable of withstanding high-intensity cutting, general purpose milling and gives improved surface finishes at higher feed rates, especially when copy milling.

BulletPoint5 : Package:1pc;Multiple sizes and hardness to choose from, catering to different work requirements

CutType : Center Cutting

CutType1 : Finishing

CutType2 : Roughing

EndCutType : Ball End

ExternallyAssignedProductIdentifier1 : 0764549879489

ExternallyAssignedProductIdentifier2 : 764549879489

FinishType : AlTiN

GpsrSafetyAttestation : 1

HelixAngle : 35 degrees

IncludedComponents : Pack

ItemName : WKSTOOL Solid Carbide Ball Nose End Mill Metric Upcut CNC Bits Cutter Tool for Non Ferrous Aluminum Copper Alloys (2Flutes 65HRC, 0.4mm Mill Dia-0.8mmLg.of Cut-4mmSHK Dia-50mmOAL)

ItemPackageDimensions_Height : 0.59 inches

ItemPackageDimensions_Length : 5.51 inches

ItemPackageDimensions_Width : 3.94 inches

ItemPackageQuantity : 1

ItemShape : Round

ItemTypeKeyword : ball-nose-end-mills

Manufacturer : WOKESI

Material : Tungsten Carbide

NumberOfCuttingEdges : 2

NumberOfFlutes : 2

NumberOfItems : 1

PartNumber : SBNM

ProductDescription : 1.Guaranteed Quality:Our end mills are subjected to rigorous quality control tests before leaving the factory. Each end mill is inspected under high magnification to ensure that it meets our stringent standards.

2.Solid carbide tools offer long tool life and faster cutting speeds than other substrates,but more brittle.Make sure work piece and machine are stable,use hydraulic chucks,high quality collet chucks,or shrink fit chucks.

3.Please adjust the speed,feed and cutting depth according to actual cutting conditions.Tool overhang,please use the required amount of minimum size,amount of long overhang is high vibration,turn it to lower the number of feed,when the tool overhang length is longer,please adjust the speed.feed and cutting depth.

4. Adapt to several kinds of cooling conditions, for example oil mist,water,oil,air cooling.can be used for dry machining.

5.The design of a two flute ball end mill allows for plenty of chip evacuation making them most effective in contouring deep pockets in molds and dies. Four or more fluted ball nose end mills have less chip evacuation due to their design but with multiple cutting edges they can produce very smooth finish by running lighter chip loads, without sacrificing a high rate of production.

ProductSiteLaunchDate : 2024-04-08T10:49:39.456Z

Size : 0.4mm Mill Dia-0.8mmLg.of Cut-4mmSHK Dia-50mmOAL

Style : 2Flutes 65HRC

SupplierDeclaredDgHzRegulation : not_applicable

SupplierDeclaredHasProductIdentifierExemption : 1

ToleranceHeld : -0.0015

UnitCount : 1

UnspscCode : 27112803