Product Information

Specification

Brand : TITAN

BulletPoint1 : Premium Sub-Micrograin Solid Carbide

BulletPoint2 : Made in USA

BulletPoint3 : 5 Flute Single End Stub

BulletPoint4 : Center Cutting

BulletPoint5 : 45 Degree

CutType : Square Nose

CutType1 : Center Cutting

CutType2 : Square

CutType3 : Finishing

EndCutType : Center

ExternallyAssignedProductIdentifier1 : 0789330740809

ExternallyAssignedProductIdentifier2 : 789330740809

FinishType : Unfinished

IncludedComponents : htlcsmroa220105hh0334

IsValueStoresItem : 1

ItemName : Titan TC61420 Solid Carbide End Mill, Stub Length, 5 Flute, Square End, 45 degree Angle Helix, Uncoated, 5/16" Cutting Diameter, 2" Overall Length, 1/2" Length of Cut

ItemPackageDimensions_Height : 8 inches

ItemPackageDimensions_Length : 4 inches

ItemPackageDimensions_Width : 4 inches

ItemPackageQuantity : 1

ItemShape : Round

ItemTypeKeyword : square-nose-end-mills

Manufacturer : Titan USA

Material : Carbide

ModelNumber : TNU 149026

NumberOfCuttingEdges : 2

NumberOfFlutes : 5

NumberOfItems : 1

PartNumber : TC61420

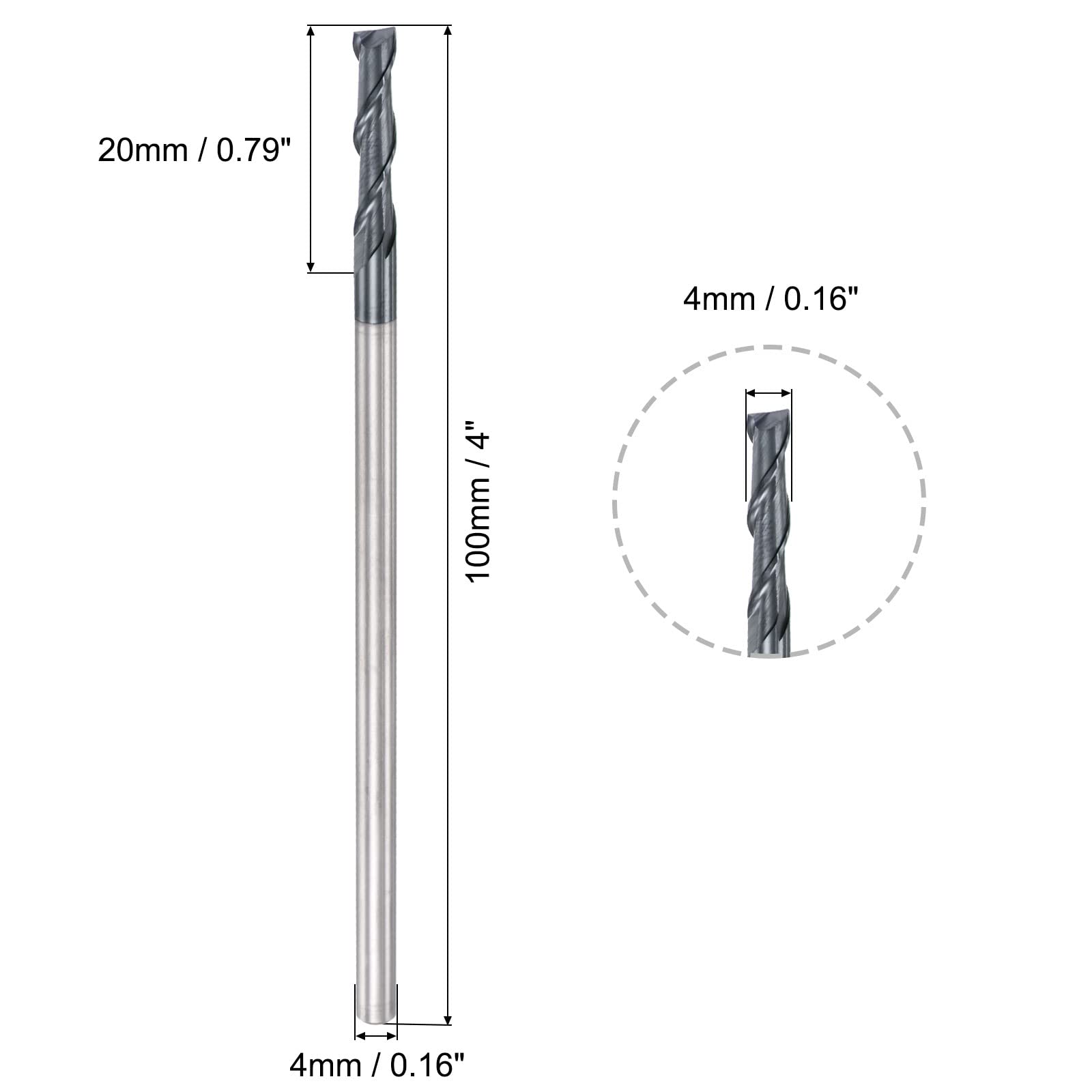

ProductDescription : Specifications:

- Cutting Diameter: 4mm / 0.16"

- Cutting Flute Length: 20mm / 0.79"

- Shank Diameter: 4mm / 0.16"

- Overall Length: 100mm / 4"

- Material: Solid Carbide (P05 Carbide)

- Finish: AlTiN Coated

- Cutting Hardness: HRC45

- Number of Flutes: 2 Flutes

- End Cut Type: Square End

- Spiral Angle: 35 Degree

- Package Content: 1pcs x Square Nose End Mill

Descriptions:

- P05 carbide end mill cutter is high hardness, wear resistance, and heat resistance. Carbide material with good milling and cutting performance, ensures high work efficiency. Carbide can run at higher speed than high-speed steel.

- Suitable for cutting carbon steel, malleable cast iron, alloy steel, die steel, etc. For shallow groove machining, side milling and finishing. Use on CNC machining centers, engraving machines and other high-speed CNC machine tools.

- Features square end cut, 2-flute design. Spiral chip space design for fast and clean chip removal. Sharp cutting edge provides smooth cutting. AlTiN composite coating can increase hardness, reduce oxidation wear for better wear resistance and extend tool life.

- The longer the length of the tool clamped by the chuck, the better. If the clamping length is shorter, you need to lower the feed rate and cutting speed to reduce vibration and extend the tool life.

- Tips: Combined with the material to be processed, select an appropriate feed rate and cutting speed to improve the tool life and obtain better processing accuracy and performance.

ProductSiteLaunchDate : 2014-10-27T08:00:01.000Z

Size : 5/16 inches

SupplierDeclaredDgHzRegulation : unknown

ToleranceHeld : Precision

UnitCount : 1

UnspscCode : 27112803