Product Information

Specification

Brand : uxcell

BulletPoint : CNC fast feed milling cutter set, HSK63A-FMB22-4″, Milling diameter 50mm, installation inner hole 22mm, 6 edges. Comes with 30pcs milling blades APKT100305PDTR

BulletPoint1 : Tap Size: M4 x 0.7 metric thread, H2 thread tolerance grade. Straight flute design, downward chip removal, fast tapping with accuracy. Titanium coating can improve wear resistance, corrosion resistance and rust protection.

BulletPoint2 : Applications: The thread tap is suitable for processing through holes or shallow blind holes. Perfect for tapping stainless steel, copper, aluminum, etc.. Micro taps are mainly used for watches and clocks, and drilling materials in low hardness, such as wood, plastic and soft metals.

BulletPoint3 : Cobalt High Speed Steel Tool: Metric tap with cobalt has higher hardness and precision, better wear resistance and toughness, higher heat resistance. It is made by adding 5%-8% cobalt to the general-purpose high-speed steel.

BulletPoint4 : Easy to Use: Used on drilling machines, tapping machines, CNC and milling machines. Use with tapping oil to get higher quality threads and more durable taps. Please add coolant when tapping and apply anti-rust oil for maintenance after use to prolong the service life.

BulletPoint5 : Tips: Machine taps are suggested to be used with tap collets with overload protection. Hand use or electric drill use is easy to cause breakage to the tap, so it is not recommended. Recommended feed rate: General steel: 6-15m/min; harder steel: 5-10m/min; stainless steel: 2-7m/min; cast iron: 8-10m/min.

ExternallyAssignedProductIdentifier1 : 0781108377804

ExternallyAssignedProductIdentifier2 : 781108377804

ExternallyAssignedProductIdentifier3 : 0769053017525

ExternallyAssignedProductIdentifier4 : 0769053016627

ExternallyAssignedProductIdentifier5 : 00769053016627

FinishType : Titanium Coated

GpsrSafetyAttestation : 1

IncludedComponents : 1

ItemName : uxcell Thread Tap Metric M4 x 0.7, Titanium Coated Cobalt HSS (High Speed Steel) 3 Straight Flutes Machine Mini Micro Screw Threading Tapping Repair Tool for Watches and Clocks

ItemPackageDimensions_Height : 1 centimeters

ItemPackageDimensions_Length : 14 centimeters

ItemPackageDimensions_Width : 10 centimeters

ItemPackageQuantity : 1

ItemTypeKeyword : thread-milling-taps

Manufacturer : uxcell

Material : High Speed Steel with Cobalt

ModelName : M4 x 0.7

ModelNumber : fde30df1-96cc-4f45-9758-fd2bba59101c

NumberOfBoxes : 1

NumberOfItems : 1

PartNumber : a24012400ux1055

ProductDescription : Specifications:

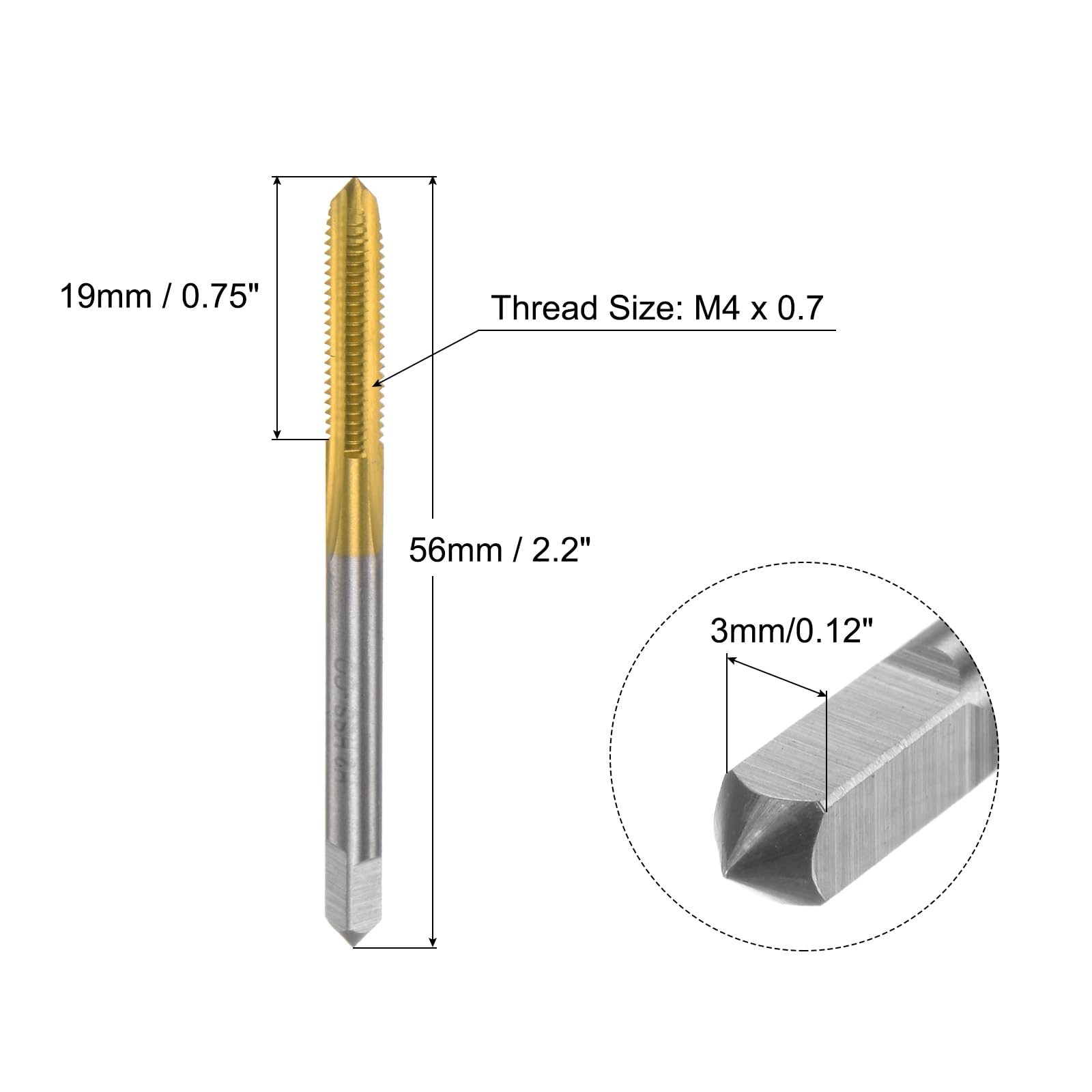

Thread Size: M4 x 0.7

Thread Length: 19mm / 0.75"

Total Length: 56mm / 2.2"

Square End Size: 3mm x 3mm / 0.12" x 0.12"

Thread Tolerance Grade: H2

Material: Cobalt HSS (High Speed Steel))

Finish: Titanium Coated

Numbers of Flutes: 3 Flutes

Cutting Direction: Right Hand

Package Content: 1pcs x Thread Tap

Descriptions:

1. Straight flute design, downward chip removal. Right hand thread cutting, clear threads, fast tapping with accuracy. Titanium coating can improve wear resistance, corrosion resistance and rust protection.

2. High speed steel (HSS) tool with cobalt has higher hardness and precision, better wear resistance and toughness, higher heat resistance. It is made by adding 5%-8% cobalt to the general-purpose high-speed steel.

3. Suitable for processing through holes or shallow holes . Perfect for tapping stainless steel, alloy steel, copper, aluminum, etc.. Micro taps are mainly used for watches and clocks, and drilling materials in low hardness, such as wood, plastic and soft metals.

4. Used on drilling machines, tapping machines, CNC and milling machines. Use with tapping oil to get higher quality threads and more durable taps. Please add coolant when tapping and apply anti-rust oil for maintenance after use to prolong the service life.

5. Machine taps are suggested to be used with tap collets with overload protection. Hand use or electric drill use is easy to cause breakage to the tap, not recommended. Recommended feed rate: General steel: 6-15m/min; harder steel: 5-10m/min; stainless steel: 2-7m/min; cast iron: 8-10m/min.

ProductSiteLaunchDate : 2024-02-28T11:43:29.205Z

Size : M4 x 0.7

SpecificUsesForProduct : Machine Use

Style : Straight Flute

SupplierDeclaredDgHzRegulation : not_applicable

SupplierDeclaredHasProductIdentifierExemption : 1

UnitCount : 1

UnspscCode : 31161500