Product Information

Specification

Brand : Groco

BulletPoint : Great Product

BulletPoint1 : High Impact Resistance

BulletPoint2 : Saltwater/Freshwater Resistant

BulletPoint3 : Excellent adhesion to Wood, Steel, Aluminum, Soft Metals, Concrete, Ceramic, Fiberglass, Composites

BulletPoint4 : Low Shrinkage; Withstands Wide Range of Temperatures

BulletPoint5 : Can be Mixed with Sand to Create a High Strength Mortar for Concrete Repair

Color : No Color

ExternallyAssignedProductIdentifier1 : 742985128651

ExternallyAssignedProductIdentifier2 : 0742985128651

Hazmat : auto-grounding

ImportDesignation : Made in the USA

IncludedComponents : Great Product

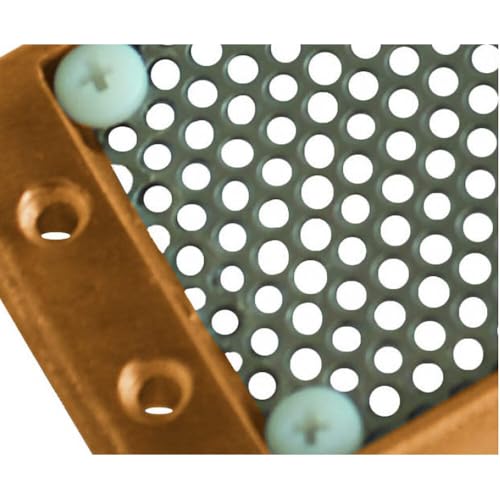

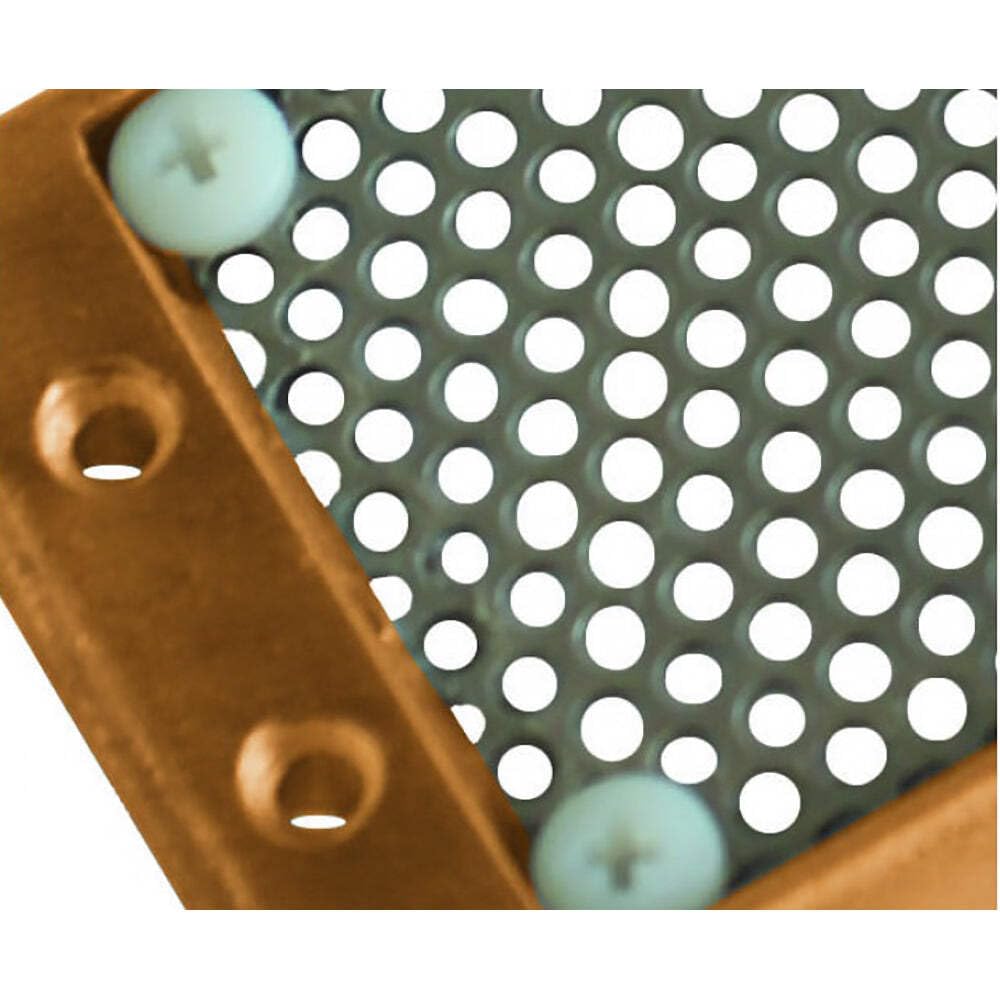

ItemName : GROCO 93-3000-03 Stainless Steel Replacement Screen f/APHS-3000 - Size 3 (.188") Perforation Diameter

ItemPackageDimensions_Height : 1 inches

ItemPackageDimensions_Length : 9 inches

ItemPackageDimensions_Width : 6 inches

ItemPackageQuantity : 1

ItemTypeKeyword : boating-tools

Manufacturer : GROCO

Material : Plastic

ModelName : 93-3000-03

ModelNumber : 93-3000-03

NumberOfItems : 1

PackageLevel : unit

PartNumber : 93-3000-03

Pattern : Solid

ProductDescription : 103 LVX Epoxy laminating epoxy is a new and improved formula. It provides high tensile strength while maintaining a very low viscosity to aid in wetting out fiberglass. This enables the laminator to produce high tensile strength lay-ups with maximum “wetting out” and a minimum of bubbles.

103 LVX can be used on warehouse docks, floors, sidewalks, walls, and concrete. 103 LVX can be mixed with sand to fill in large holes and cracks in concrete and has enough strength to withstand heavy forklift traffic. 103 LVX seals against leaks without shrinkage and is also used to laminate fiberglass cloth to existing fiberglass, wood, metal, or concrete.

Application: Mix very well, scraping down the sides of the mixing bucket to ensure that all of the resin and hardener gets mixed together.

Application for Heavy Duty Non-Skid Surface for Metal, Concrete, Wood, or Fiberglass:

1. Surface must be clean, dry, and free from oil or grease.

2. Mix the 103 LVX kit. Roll or brush evenly on surface.

3. While epoxy is wet, broadcast quartz aggregate evenly on surface (other non-skid particles may be substituted for quartz). The epoxy should stay wet enough to receive the aggregate for at least 1 hour. Use aggregate size in accordance to roughness desired - #30-65 aggregate is an average non-skid surface.

4. Continue above procedure until entire surface is covered with aggregate.

5. Allow to dry. Sweep off loose aggregate.

6. Apply a thin coat of mixed 103 LVX epoxy over the aggregate surface. Squeegee the epoxy down tight so that there are no puddles of epoxy. The surface should have an even textured appearance.

Working Time: Mixed product must be used within 30 min.

Gel Time Thin Coats 4-6 hours - Thick Coats 2-4 Hours.

Set Time Thin Coats 6-8 hours - Thick Coats 4-6 Hours.

Cure Time 24 to 72 Hours

ProductSiteLaunchDate : 2019-12-06T14:43:49.183Z

Size : One Size

SupplierDeclaredDgHzRegulation : not_applicable

UnitCount : 1

UnspscCode : 43210000

VolumeCapacityName : 3 quarts

WarrantyDescription : Warranty