Product Information

Specification

Brand : SÜA

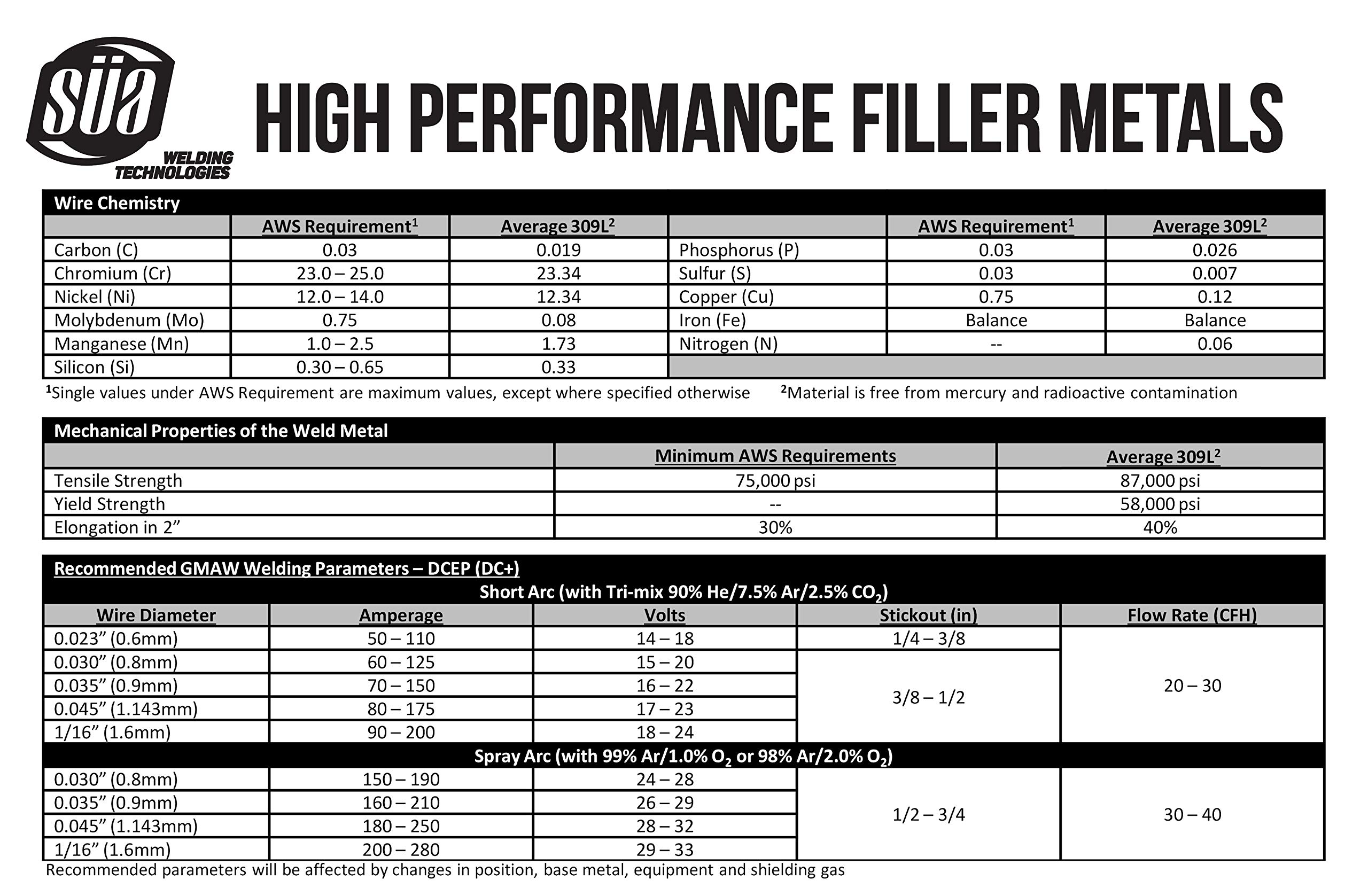

BulletPoint1 : For welding heat resistant 22-25% chromium – 12-13% nickel stainless steels such as 309/309L to itself, to other austenitic Cr – Ni grades such as 304L, 308L, 310, 316L, 321 or 347 as well as martensitic grades such as 410, 420, 431, and ferritic stainless grades such as 430, 442, and 446; all of these stainless steel grades can be welded to each other or to mild and carbon steels.

BulletPoint2 : The maximum carbon content of less than 0.03% preserves the intergranular corrosion resistant properties of the weld deposit and weld zone, yielding x-ray quality welds.

BulletPoint3 : Common applications of 309L stainless include welding of dissimilar steels or overlaying unalloyed structural steels found in furnace parts, kiln linings, heat treatment containers, forgings and castings in chemical, petrochemical, power generation and pharmaceutical industries.

BulletPoint4 : Spool Weight: 2 Lb of Wire - Available Sizes: 0.030"and 0.035" - Spool Quantity Packs: 1 Spool, 2 Spools, 4 Spools, and 6 Spools

BulletPoint5 : For shielding gas use 100% Argon or Argon/Helium for greater penetration and higher speeds

CustomerPackageType : Standard Packaging

ExternallyAssignedProductIdentifier : 8033675670911

ExternallyAssignedProductIdentifier1 : 703856605176

ExternallyAssignedProductIdentifier2 : 0703856605176

ExternallyAssignedProductIdentifier3 : 00682488120038

FinishType : Polished

ItemDisplayWeight : 4 pounds

ItemForm : Coil

ItemName : SÜA - ER309L - MIG Stainless Steel Welding Wire - 2 Lb x 0.030'' (2 SPOOLS)

ItemPackageDimensions_Height : 8.128 centimeters

ItemPackageDimensions_Length : 23.876 centimeters

ItemPackageDimensions_Width : 16.764 centimeters

ItemPackageQuantity : 1

ItemShape : Round Rod

ItemTypeKeyword : welding-wire

Manufacturer : TGB

Material : Stainless Steel

ModelNumber : ER4043

NumberOfItems : 1

PartNumber : 309LW2x30_2

ProductDescription : ER309L - WIRE - MIG (GMAW) - STAINLESS STEEL AWS A5.9 Welding Positions: All INTRODUCTION: High-alloy solid wire electrode, annealed and layer wound, excellent welding characteristics thanks to high Si content, suitable for dissimilar joints and buffer layers, maximum operating temperature 300 °C USES: Austenite-ferrite joints (dissimilar), cladding, corrosion-resistant layers on non-alloyed construction steels, buffer layers. CHEMICAL COMPOSITION (%): Chemical Composition C Mn Si Cr Ni Requirement ?0.030 1.00~2.50 0.30~0.65 18..00~20.00 11.00~14.00 Typical test result 0.023 1.90 0.42 19.12 12.59 Chemical Composition Mo P S Cu Requirement 2.00~3.00 ?0.030 ?0.030 ?0.75 Typical test result 2.59 0.009 0.008 0.28 WELDING PARAMETERS (DC+): Diameter (mm) ?0.8 ?1.0 ?1.2 Welding Current (Amps) 70~150 100~200 140~220 NOTES: 1. Shield gas: Must ensure not to operate with impurity shield Gas, Recommended Rate of mixed gas: Ar + 1-3% O2. 2. Operation flow rate of shield gas: 20-25L/min. 3. Electrode extension: 15-25mm 4. The welding should be operated in clean surface without rust, moist, oil contamination and dust. 5. To avoid bubbles protect from wind its speed reach 1.5 m/s. The above parameters are for reference purpose and depend on diverse factors. Run tests, evaluate and set your welding parameters before starting the welding job.

ProductSiteLaunchDate : 2016-09-22T15:20:58.249Z

Size : 0.030" - (2 Spools)

SupplierDeclaredDgHzRegulation : not_applicable

UnitCount : 1

UnspscCode : 23271800